Effect of Liquid Properties in Pipetting

The pipettes used in laboratories today are usually adjusted to deliver a desired volume using water. As a reference liquid, water is accepted by the authorities, since the physical properties of water are well-known in different ambient conditions. In a real laboratory environment, however, the liquid transfer is always influenced by a combination of many factors. Liquid properties belong to these factors and they may have a considerable effect on the dispensed volumes. The influence of several different properties is discussed here.

Concept explanations

In this article the following definitions apply:

Calibration = determination of the difference between the mean volume of the measurement series and the selected volume on the pipette display.

Adjustment = altering the pipette settings for the actual volume to correspond to the selected volume.

CV% = coefficient of variation, a relative value obtained from statistical standard deviation and the mean value of measurements.

Liquid properties influencing pipetting results

The majority of pipettes used in laboratories utilise the air piston principle. This means that there is an air space between the liquid and the actual piston. Most of the liquids can be transferred more accurately with an air piston pipette than with a positive displacement pipette (based on direct contact between the liquid and piston). However, some liquid characteristics and ambient factors may cause deviations in the delivery of liquid. The different behavior is made possible by the existing air space and this should be taken into account when pipettes are used.

Theoretical and empirical approaches to explain the observed influences have been discussed in the end-user support material provided by several pipette manufacturers. However, it may be difficult to apply scientific theories to practical situations.

The real liquid transfer is always influenced by a combination of several factors, including the liquid properties. Therefore, the evaluation of a particular case can be challenging. To make the approach easier, several individual factors are explained here. Thus, the combined effect can be better understood.

Liquid density

With air piston pipettes the air space between the liquid and piston acts in a similar way to a spring. This means that when a pipette is adjusted to deliver an exact volume of water, the same pipette delivers a larger volume of a liquid of lower density. This is because the same volume which was obtained with water is lighter with the less dense liquid. The air space (spring) is not in a balance state with this volume and therefore draws up the liquid slightly more than with water. An inverse effect is caused by a more dense liquid. The higher density imposes an increased force on the air space, causing it to stretch and resulting in a smaller liquid volume being aspirated into the tip.

The effect of density can be reduced by transferring a different amount of liquid. It is not recommended to adjust the volume delivery to correspond the display setting to other liquids than water. This is because pipettes are used to deliver several different liquids, each having different properties. Using a reference liquid such as water is more reliable in following the pipette performance. The effect of other liquids can be evaluated by calibration and changing the delivered volume accordingly (that is, if the calibration result gives a 5 µL smaller volume at the 500 µL setting, the correction can be made by setting the delivery volume to 505 µL to compensate for the difference).

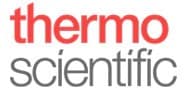

Density always has a combined effect with other factors, and therefore, good examples are difficult to present. Inorganic salt solutions may be used as one. Using a 1000 µL setting, the pipette gives approximately 1 µL smaller volume values when pipetting a saturated NaCl-water solution compared to pure water. Another salt solution may give different results. Figure 1 shows the results with two salt solutions (saturated NaCl solution and 20 w-% Na2CO3 solution) compared to pure water. A standard FT 1000 tip was used.

Figure 1 (left). Effect of liquid density on the delivery volume. Differences between water, saturated NaCl solution and 20 w-% Na2CO3 solution. Individual measurement variation shown along with the average value of test results.

Figure 3 (right).Evaporation causes the liquid to squeeze through the tip orifice if the tip is not pre-wetted. On the right a dry tip, and on the left a pre-wetted tip with a coloured ethanol solution 15 s after the aspiration.

Vapour pressure and evaporation

Every liquid forms a balance between liquid and gas states. To reach this equilibrium, the liquid evaporates until a certain concentration is present in the surrounding atmosphere. Vapour pressure is a liquid property that describes how fast the liquid tends to reach the equilibrium point. Liquids with a large vapour pressure begin to evaporate into the tip air space when the liquid is aspirated into the tip. The air space expands due to the evaporated liquid, and since there is no other way to relieve the pressure, the liquid begins to squeeze out through the tip orifice. This is often erroneously considered as leaking, when it in fact is a natural phenomenon. The first doses of a pipetting series also give smaller volumes, since the expansion of the gas phase prevents some of the liquid from entering the tip.

Evaporation is a continuous phenomenon. Therefore, it is good to remember that volatile liquids also evaporate during dispensing. The volume entering the target vessel is smaller than the amount that was in the tip before dispensing. This can be notable especially with small volumes.

To reduce the effects of evaporation, it is recommended to pre-wet the tip. Aspirating and dispensing the liquid a couple of times brings the air space closer to the balance point. During the actual dosing series after pre-wetting, the difference between doses is smaller and the “leaking” phenomenon is negligible.

It is worthwhile to note that some liquids, such as alcohols, have a so-called windshield wiper effect. The lubricating grease in the pipette can be swept away from the sliding surfaces after several pipettings and the piston begins to jam. This can be fixed by moving the plunger a few times without the liquid to respread the grease.

Viscosity

Viscosity is a property that restricts movement. Therefore, a liquid with a high viscosity (for example, glycerol) flows into and out of the tip very slowly. If the tip is withdrawn too soon from the liquid reservoir, an air bubble is also drawn into the tip, reducing the liquid volume.

During dispensing, viscous liquids leave a film on the walls of the tip, and the film flows down more slowly than most of the liquid mass. If the plunger is pressed too quickly, some of the liquid remains in the tip due to this slow movement. The results can be improved by reducing the pipetting speed. Slow aspiration allows the liquid to rise to an equilibrium level and slow dispensing reduces the effect of the liquid retention film. Additionally, it is helpful to use the reverse pipetting technique, which also reduces the effect of liquid retention. Using wide-orifice tips eases the liquid aspiration and dispensing, allowing the liquid to move more freely through the tip orifice.

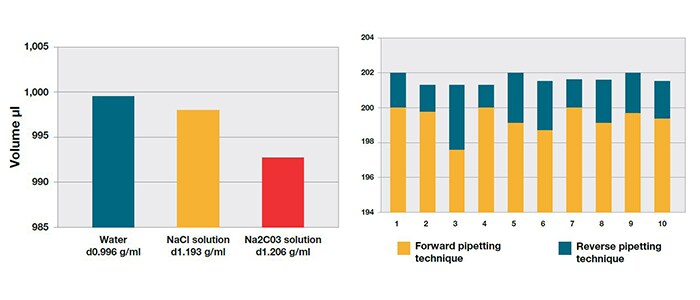

Figure 3 shows the effect of the used pipetting technique on the results with glycerol. The curves are average values from three separate measurement series with each technique. The above-mentioned precautions have been taken into account. Individual CV% values varied from 0.69% to 1.15% with the forward method, and from 0.27% to 0.50% with the reverse method. The use of the reverse method reduces result deviation but also increases the volume due to a higher liquid column. The pipette was adjusted for glycerol using the forward method.

Surface tension

Surface tension describes the strength of intermolecular forces which hold the liquid bulk together. A good example of a liquid with a high surface tension is water. Surfactants like Tween are used in several current laboratory applications, such as microplate immunoassays. The used additives lower the surface tension of the media, which, for example, improves the specificity of the analysis.

Because the surfactants reduce the surface tension, the wetting ability of the liquid changes. A very thin film of liquid remains on the tip walls, flowing down more slowly than most of the liquid mass. The effect resembles the behavior of viscous liquids, but the remaining liquid film is much thinner. Sometimes with colourless liquids, the film is undetectable. After the dispensing movement, some of the liquid may still remain in the tip.

The additives may also cause a foaming tendency in the liquids. Due to this, some of the liquid may be trapped into the foam and remain in the tip after dispensing. This is because the combined volume of the liquid and foam is usually larger than the dispensing movement volume. Foam may also cause unwanted disturbances in further application procedures (for example, photometric measurements).

The effect of a lowered surface tension can be reduced by slowing the pipetting speed. Additionally, the liquid retention effect can be reduced by using the reverse pipetting technique.

Discussion

The physical properties of liquids may cause notable deviations in liquid handling processes unless they are taken into account. These properties cause different behaviors in liquid dosing, depending on the situation. It is possible to reduce the observed effects by changing, for example, the pipetting speed and pipetting technique. It should be kept in mind, however, that liquid properties are not the only influencing factors, but the result is always a combination of different phenomena. Therefore, a calibration should be performed to confirm the actual effect.

References:

1) Koivisto, S., The Tip of Perfection, Factors Affecting Pipetting Performance, Laboratory Equipment 8

(2007) 38-40.

2) International standard, EN ISO 8655 Piston-operated volumetric apparatus, ISO, Geneva 2002.

Content provided by: